CONVEYING SYSTEM

A Conveying System is an engineered material handling solution designed for the efficient movement of bulk solids such as biomass, coal, ash, and agro-residues across industrial processes. PP Boilers provides robust, automated conveying systems that ensure smooth integration with boiler operations, reduce manual handling, and support high-capacity, continuous production environments. These systems are tailored to handle a wide range of materials, temperatures, and plant layouts with minimal maintenance and energy-efficient performance.

Belt Conveyor Capacity

Up to 500 TPH (Tons Per Hour)

Material Types

Coal, biomass, ash, grains, pellets, etc.

Temperature

Up to 150°C (for ash and hot materials)

Compliance

Meets industry safety and quality standards

Technical Specifications:

- Handled Materials: Suitable for biomass, coal, RDF, bagasse, husk, ash, pellets, and other granular or lumpy bulk solids

- Conveyor Technologies: Includes belt, chain, screw, bucket elevator, and pneumatic conveying systems tailored to material type and plant layout

- Capacity: Supports high-volume transport—up to 500 TPH (belt and chain systems)

- Operating Temperatures: Withstands up to 150°C for hot ash and abrasive materials

- Inclination Capability: Up to 30° for inclined belt conveyors; vertical lifting in bucket elevators

- Automation & Monitoring: PLC/SCADA integration with sensors for load, speed, misalignment, and emergency control

- Construction Materials: Options include mild steel, galvanized steel, SS 304/316, and wear-resistant alloys for durability under corrosive or high-wear conditions

Details:

PP Boilers offers a range of conveying systems tailored to industrial needs. Key systems include:

- Belt Conveyors: Ideal for continuous horizontal or inclined transport of free-flowing bulk materials such as coal, ash, and biomass over long distances with minimal energy use.

- Chain Conveyors: Engineered for rugged, heavy-duty handling of abrasive or lumpy materials like biomass bales, bagasse, chipped wood, and slag in enclosed or open configurations.

- Screw Conveyors: Suitable for controlled, enclosed transport of fine, powdery, or granular/grainy materials such as biomass, husk and fly ash typically over short to medium distances.

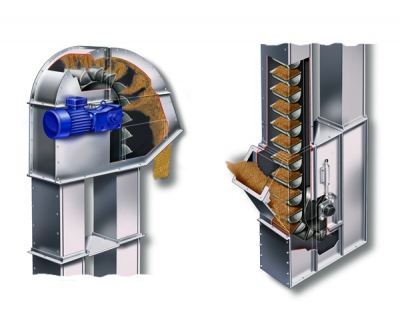

- Bucket Elevators: Efficient for vertical lifting of bulk solids like husk, grains, pellets, and fertilizers, with minimal space footprint and dust generation.

- Pneumatic Conveyors: Use pressurized air or vacuum to convey lightweight, dry materials such as sawdust, fly ash—ideal for flexible routing and dust-free transfer.

- Handled Materials: Suitable for biomass, coal, RDF, bagasse, husk, ash, pellets, and other granular or lumpy bulk solids

These systems are integrated with boilers and industrial processes to ensure seamless material flow and operational efficiency.

Key Points:

- Industry Adaptability: Designed for sectors such as thermal power, cement, distillery, agro-processing, grain handling, and WTE facilities

- Automated Performance: Supports fully automated operations with VFD drives, real-time feedback, and overload protection

- Seamless Integration: Ensures synchronized feeding into boilers, hoppers, or silos without interruption to process flow

- Ash & Slag Handling: Tailored extraction systems for fly ash, bottom ash, and coarse slag discharge

- Dust & Emission Control: Enclosed or sealed systems equipped with integrated dust suppression and fire safety (NFPA-compliant)

- Process-Specific Customization: Engineered based on material flow behavior, particle size, moisture content, and handling distance

- Easy Maintenance Access: Simplified maintenance through accessible tensioners, rollers, and lubrication points

- Built-In Safety Features: Systems include zero-speed detectors, belt tracking sensors, and emergency pull cords

Advantages

- Increased efficiency in material transport.

- Reduced labor costs through automation.

- Improved safety in handling materials.

- Customizable designs to meet specific requirements.

- Enhanced reliability and durability of operations.

- Flexibility to transport various types of materials.

- Low maintenance requirements for certain systems.

- Potential for energy savings with efficient designs.

- Supports high-volume production and processing.

- Facilitates better inventory management and control.

Applications

- Manufacturing and assembly lines.

- Food and beverage processing.

- Mining and mineral processing.

- Packaging and distribution centers.

- Agriculture and grain handling.

- Waste management and recycling facilities.

- Pharmaceutical production.

- Chemical processing plants.

- Construction and building materials handling.

- Retail and warehousing operations.

BELT CONVEYOR

(Transport Fuel/Ash)

BUCKET ELEVATOR

(Vertical Material Handling)

CHAIN CONVEYOR

(Heavy Material Transport) 1