Our Products

Spent Wash (Slop) Fired Boiler for Distillery

Pressure & Process Boilers introduce Spent Wash/Vinasse fired water Tube Boiler to Brun 100% Slop into the Boiler and Keep Industry on Zero liquid Discharge.

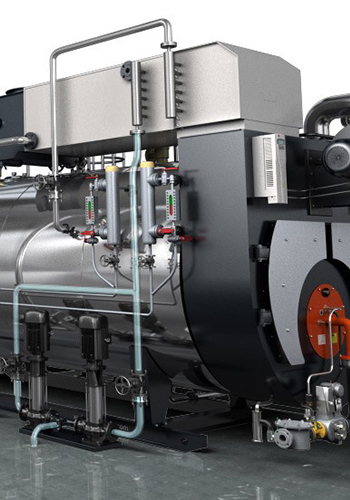

Skid Mounted Process Boilers

Minimum spares required for installation. Minimum time period required for installation. Minimum foundation required.

Bi-Drum Water Tube Boiler

Unique design with ample water holding capacity, tall furnace for complete combustion of fuel particles within the furnace zone, High-Pressure Boiler with highly

Rice Straw/Sugar Cane Leaf Fried Boiler

Pressure & Process Boilers introduce Rice Straw Bale Fired water tube Boiler to Generate the steam for Process and Power generation at minimum Running Cost

Waste Heat Recovery Boiler

The Waste Heat Boiler produces steam at required pressure and temperature. The boiler proposed is of Water-Tube type with flue gases coming from the Sponge Iron Kiln

Gas Fired Steam Boiler

We make custom made Gas Fired Boilers to suit the flame length and combustion parameters of various different burners like Weishapt, Reillo, Ecostar & Bentone along with

Our Products

-

High Pressure Boilers

-

Process Boilers

-

Skid-mounted Boilers

-

Waste Heat Recovery Boilers.

-

Spend-wash Boilers.

-

Rice-Straw Fired Boilers.

-

Special-designed Boilers.

-

Un- fired Vessels.

-

High Pressure Vessels and Tanks.

-

EPC Projects.

-

Thermal Fluid Heaters.

-

Hot Air Generators

-

Air Pollution Control equipment’s.

-

Fabrication of all types of Structural work, Plate Work, t.a. & vessels, IBR & NON IBR piping’s,

Skids & other MSCL Fabrication

-

Retrofitting of all type of Boilers, Pollution Control Equipment’s to enhance capacity, performance and efficiency.

-

Site construction and commissioning.

-

Troubleshooting and after sales services.

-

Supply of spares of Boiler, Power Plant, Sugar Plant,Distillery including Electrical and Instrument Spares.

-

Plant inspections.

-

Residual Life Assessment of Boilers.

-

Energy Audits of the Plant.