Spent Wash (Slop) Fired Boiler for Distillery

PP Boilers specializes in providing state-of-the-art spent wash-fired boilers tailored to the distillery industry. By implementing our solutions, distilleries can significantly improve efficiency, reduce waste, and enhance sustainability. Contact us to learn how our boilers can transform your operations into an eco-friendly powerhouse!

Technical Specification

Industries : Molasses Based Distillery

Capacity : 10 TPH to 80 TPH

W.P : 47 kg to 52 kg

Temperature : 440° C

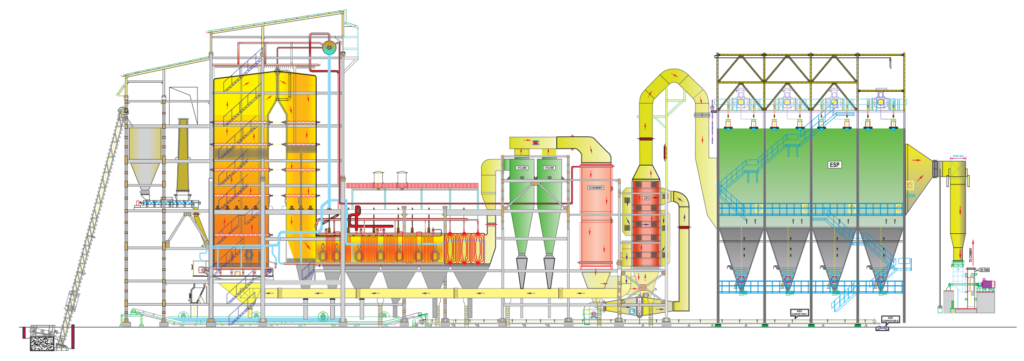

Description: Pressure & Process Boilers introduce Spent Wash / Vinasse fired water Tube Boiler to Brun 100% Slop into the Boiler and Keep Industry on Zero liquid Discharge. The proposed boiler is a Single-Drum Water Tube Boiler with multi-pass furnace design. PPB proposed both external / internal fired super heater designs. The boiler is design on 75% spent wash / vinasse in combination with supporting fuels like RiceHusk / Coal / Biomass and the slop contain Chlorine, Sulphur, K 2 O and oxides of Sodium and magnesium keeping in view of impurities in fuel the boiler is designed to avoid Fouling/Slogging problems.

Technology: The concentrated slops with 55 to 60% solid contents are injected into the furnace with the help of high pressure pumps and special-designed spray nozzles. The slops burns completely in free board and it does not reaches bottom of furnace i.e. bed or top of grate. The flue gases then pass through multi-furnace zone and major ash particles are separated at furnace outlet. The flue gases then pass through evaporator/super heater section in case of internal super-heater they pass through Evaporators, Economizer, Air Pre Heater, and Cyclone Bag House / ESP. The system is equipped with number of customized soot blowers for on-line cleaning.